|

The

FuzyPro 1/16 DIN Fuzzy Logic Temperature Controllers can

easily be configured to provide precise control. The advanced

Smarter Logic "Fuzzy" allows processes to be controlled better

than ever before, with virtually no initial overshoot or temperature

variations. The

FuzyPro 1/16 DIN Fuzzy Logic Temperature Controllers can

easily be configured to provide precise control. The advanced

Smarter Logic "Fuzzy" allows processes to be controlled better

than ever before, with virtually no initial overshoot or temperature

variations.

As the control detects a process disturbance the fuzzy logic continuous

decision making function quickly returns the process value to

the setpoint. A single ramp/soak function prevents rapid temperature

changes that could damage the product being heated. An optional

dwell timer enables an event to be timed on or off when preset

temperature is attained. In addition self-diagnostic capabilities,

sensor linearization and cold junction compensation are all performed

b;y the powerful, single chip microprocessor.

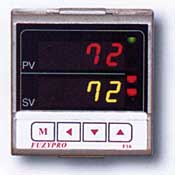

FuzyPro

1/16 DIN Fuzzy Logic Temperature Controllers

Features:

• 48mm

by 48mm Smarter Logic for superior control

• Automatic tuning of PID parameters

• Splash & chemical resistant sealed mylar front panel

• External lockout PID heating and PID cooling

• A11 control parameters front panel adjustable

• Auto/manual operation, F or C display, 3 year warranty

• Selectable

input, optional alarm or on/off delay timer

FuzyPro

1/16 DIN Fuzzy Logic Temperature Controllers

Specifications:

INPUT

|

Thermocouple

|

Type J,K,T,E,B,R,S,N

(selectable) |

|

RTD

|

PT100 ohm (DIN

or JIS) |

|

Linear

|

10-60mV configurable

input other voltage or current |

|

Display

|

In temperature

or engineering units. |

OUTPUTS

| Relay |

SPDT relay rated

3A,240v maximum resistive load |

| Pulsed

Voltage |

32VDC, 20mA maximum

|

| Current |

4-20mA, 0-20mA

maximum load 500ohms |

| Voltage |

0-10V load 500k

ohms |

| Alarm |

14 selectable

alarm modes; Process deviation and band, SPST relay rated

2A,240V maximum resistive load with adjustable hysteresis.

|

CONTROL

FEATURES

| Temperature

Range |

Selectable |

| Set

Point |

Full range adjustable

|

| Alarm

Set Point |

Full range selectable |

| Control

Modes |

Selectable control

modes

On/Off, Proportional(P),

Proportional/Integral(P/I)

Proportional with manual reset

Proportional Derivative(PD)

Proportional/Integral/Derivative(PID) |

| Proportional

Band |

0-100% of span |

| Manual

Reset |

0 to (P x span/100)

|

| Integral

(Reset) |

0 to (P x span/100) |

| Derivative

(Rate) |

0-1000 seconds

|

| Anti-Reset

Wind-up |

0-1000 seconds |

| On/Off |

Adjustable hysteresis

from 0-25.5% of span |

| Manual

Mode |

Configurable as

open loop control should sensor no longer function. |

| Cycle

Time |

0-120 seconds |

| Sensor

Break Protection |

Configurable status

of control and alarms |

| Control

Action |

Selectable-Direct

action for cooling Reverse action for heating. |

INDICATION

| Display |

4 digit red 1/2"

LED Process value Display; Green 3/8" LED Set Value display

Selectable decimal placement for normal or high resolution

display. Example: 0000;000.0; 00.00 or 0.000 |

| Status

Indicator |

2 LED's Output:

Green Alarm: Red |

| Sample

Rate |

333 milliseconds

F/C: Selectable |

| Power

Supply |

80-26OVAC 50/60Hz

Consumption: Less than 5VA |

| Data

Retention |

10 years (EEPROM)

|

| Control

Stability |

0.15%(typical)

of full scale |

| Accuracy |

±0.25%

of range: ±-1ºC or 0.5% in high resolution |

| Cold

Junction Compensation |

0.1%/ambient |

| Ext

Resistance |

100 ohms, maximum

|

| Normal

Mode Rejection |

60dB Common Mode

Rejection:120dB |

| Operating

Temperature |

14ºF - 122ºF

(-10ºc - 50ºC) Humidity: 0-90% RH |

| Vibration |

10-55Hz, amplitude

1 mm Shock: 200m.s(20g) |

For

Quick Delivery

From Stock Call

CANADA

& USA TOLL FREE: 1 - 800 - 279-9912

|